Keep manufacturing expenses lower than 25%.

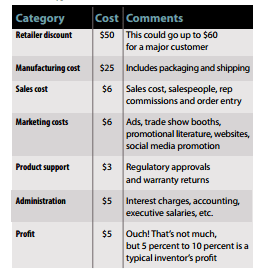

One of the most important planning aspects for inventors is determining costs associated with manufacturing, marketing and selling your product. Inventors often don’t realize that they need their product’s manufacturing costs to be only 20 percent to 25 percent of their projected retail sales price if they hope to make money. See this chart for a typical $100 retail sale:

The problem most inventors have before spending large amounts of money is not knowing how to estimate what their product will cost in large production. Often, they only have quotes for prototypes and small production runs, which can be very high.

Inventors often don’t know the impact of tooling costs, either, and how those costs should be incorporated into their final product cost. To get a better understanding of their manufacturing, I recommend inventors follow these five steps to see whether their product can make money.

1. Find two to three products that you feel will have very similar manufacturing costs to your product. If you look at the price of that product and divide it by five, you will probably be somewhat close to its manufacturing costs. That is a good starting point for the cost of your product.

2. Take the products to the local branch of SCORE (Service Corps of Retired Executives; score.org). I have found that most branches have several people with manufacturing experience, or connections that can help guide you while you figure out costs. Have the adviser explain whether there are any major differences between your product and the ones you have chosen that could result in a higher or lower price for your product.

3. If you can’t find a SCORE adviser, take the products, along with your idea, to two to three manufacturers who manufacture your type of product. Ask them if they feel the cost of your product will be similar to theirs. Again, ask for differences that would make the product more or less expensive than yours.

4. Estimated the impact of tooling costs. One component of product costs that can throw you off is that tooling costs are amortized over time and put in the product costs. So if tooling costs for a product are $50,000 and it will make 1 million units, the manufacturer will add about 20 cents to each product produced. You need input from manufacturers and your SCORE contact about getting the most cost-effective mold size.

5. Multiply your predicted production cost by five and then compare it to what you feel is the perceived value of your product. If your perceived value is about the same, or higher, after doing this, you are in great shape to make money on your invention. If not, you may need to go back and redesign your product so it is cheaper to make.

These may seem like torturous steps. But far too often, inventors with strong, saleable products continue on the invention path—spending money at every step—only to end up with a product they can never make money on because production costs are too high for the product’s perceived value. The time to discover this is early, when you have time to make corrections by adding features or redesigning your product to cut costs